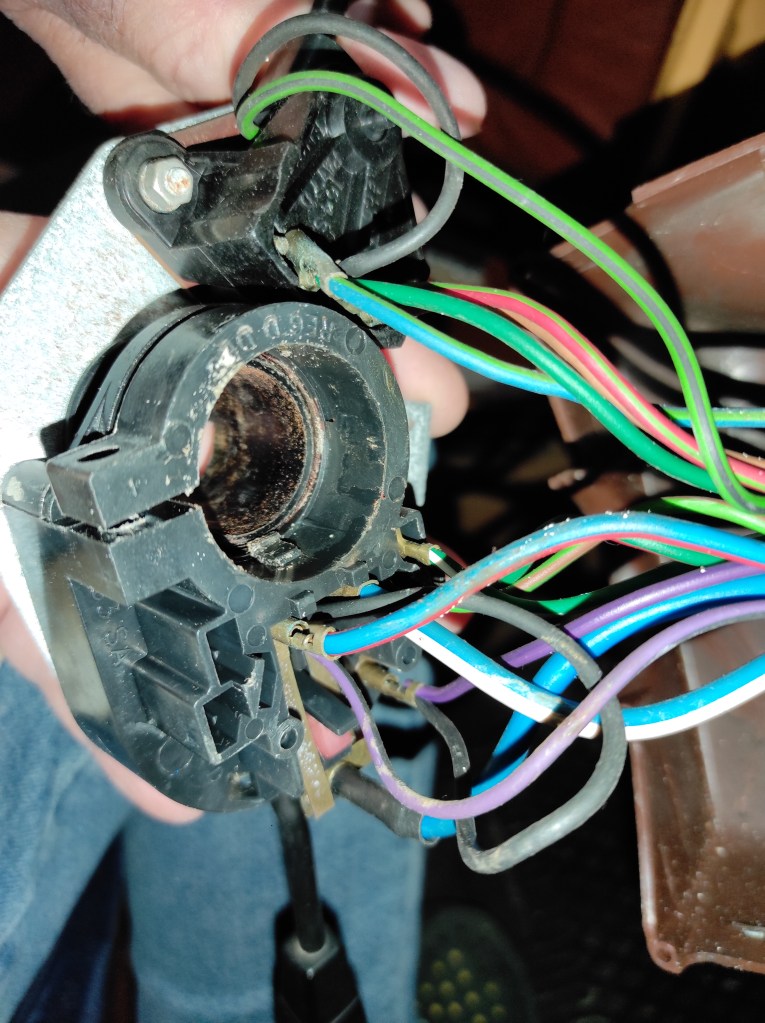

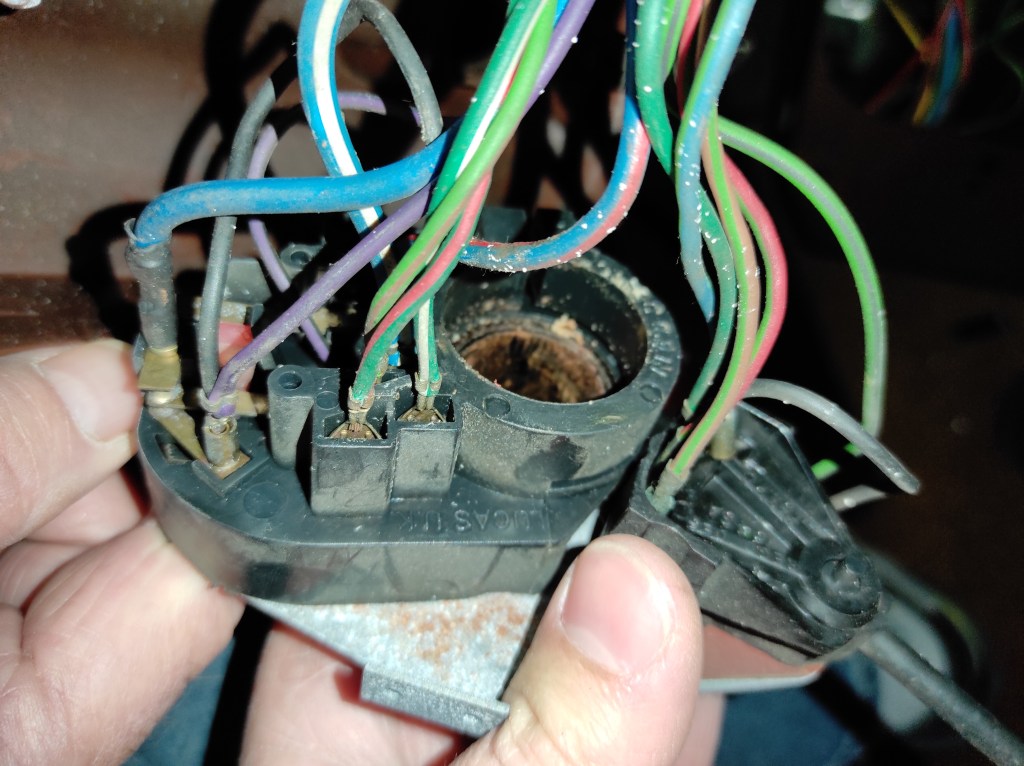

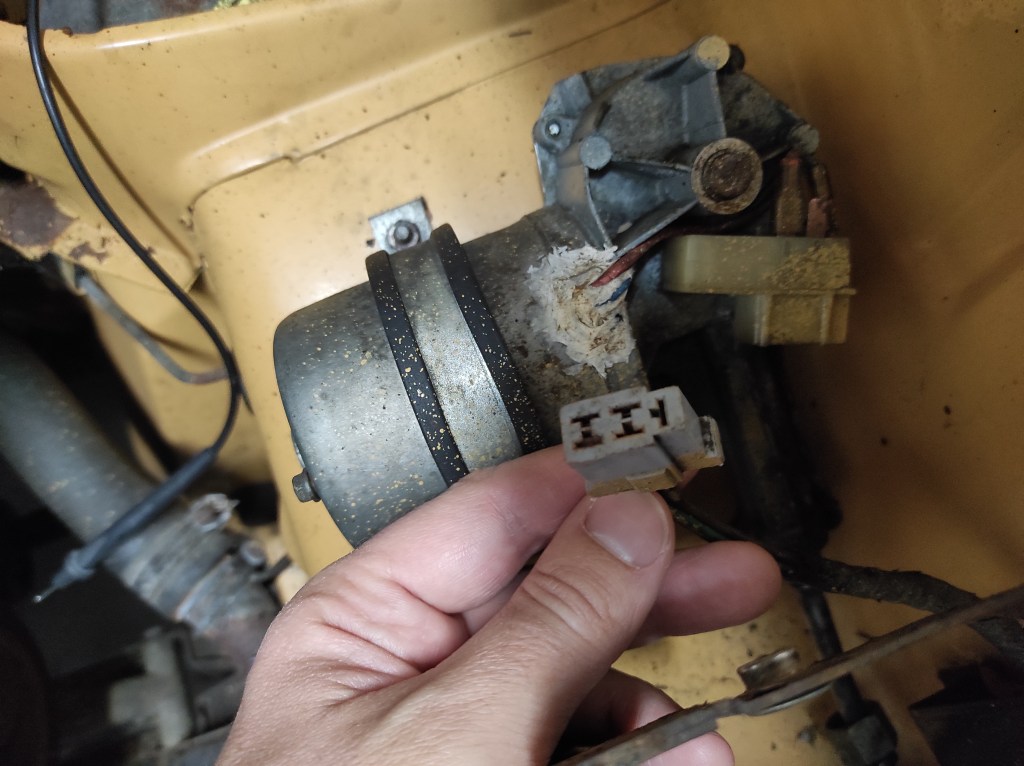

When we first saw Agnetha in the museum it looked like she had a broken spark plug. I didn’t think this would be a huge problem but after she was delivered I realised something else was going on. Yes, she does have a broken spark plug but lodged inside was a lump of Wakandan steel that was impossible to extract or drill out. After removing the alternator I found part of a broken tool lodged in the mounting bracket, and the broken end matched perfectly the lump of Captain America’s shield that was sticking out of the spark plug hole.

The tool has “YATO” branding which is a popular Polish toolmaker. I’m not sure how popular they are in Sweden, and I’ve no proof either way that someone smashed a piece of toolsteel into my block in *this* country or Sweden, so no point pointing the finger (even though I’m absolutely pointing the finger).

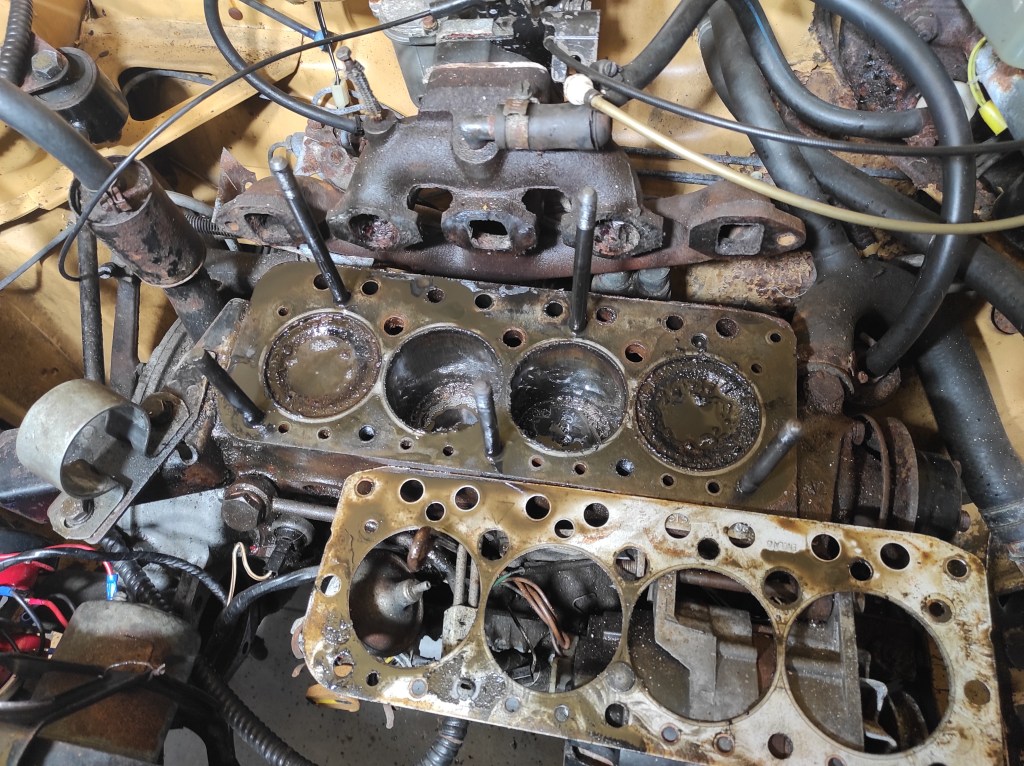

In any case the engine, although advertised as turning, was only able to turn a couple of degrees and it has been stood for some 33 years, so I bought the car knowing it would probably involve an engine rebuild. I’ve never taken the head off an engine before, let alone rebuilt one, but what could be better to learn on than a seized A-series? “Off with her head!”

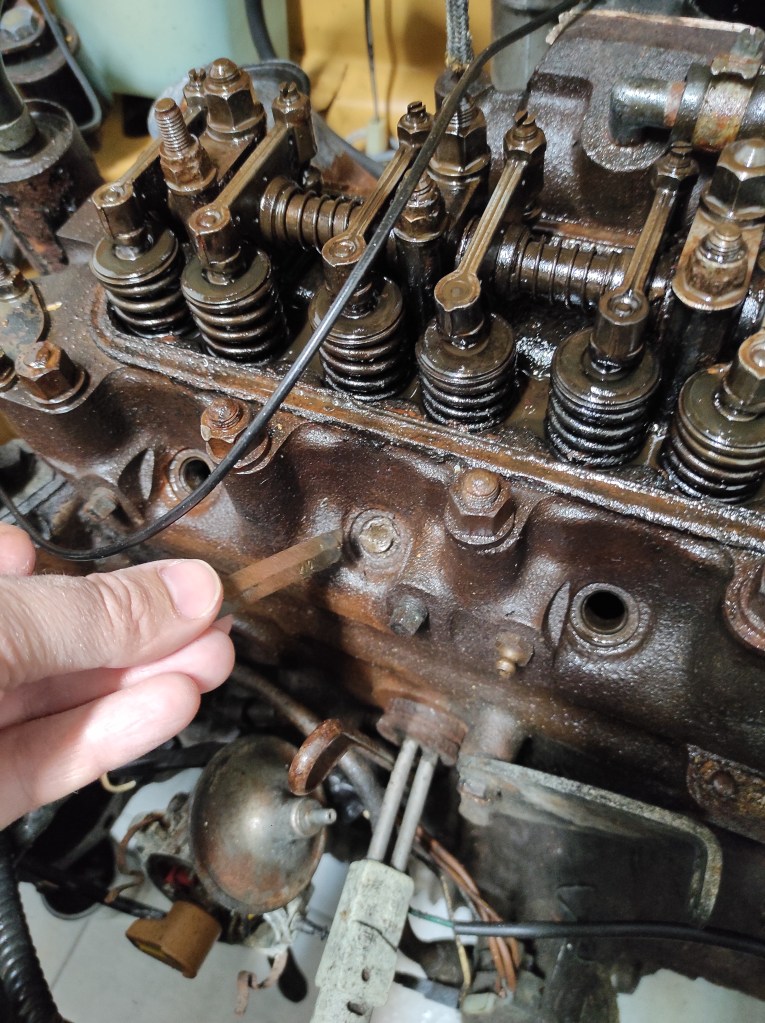

Taking the head off was a great workout. This video from All Things Alex was really helpful. In terms of engine rotation (or lack of) it looks like number 3 cylinder is holding everything back – possibly some corrosion around the piston rings? The other cylinders seem to be free. I’ve left them to soak in WD40 and we’ll come back to deconstructing that lot another day. The valves are crusty as hell – I will probably replace them along with the springs. But the rocker assembly is in good nick.

Getting the tool out was easy – just went in from the combustion chamber end with a screwdriver and smacked it with a hammer – ping! I tried to drill the remains of the spark plug itself and get it to turn with a bolt, but it seems to have become one with the head. I will probably have to drill the whole thing out and replace the thread with a repair kit. Then give the head a good clean, repaint it, replace the valves, polish and it should be good as new.