We’re almost ready to re-install the cylinder head and try for a first start. One minor set-back is that I just noticed at least one of the valve pushrods are bent! This particular one has some impressive witness marks as it gouged itself against the block – very nice. Due to the cleanness of the marks I guess this happened fairly recently.

Given the starter solenoid was dead when I got the car, and picturing the kind of force needed to bend a rod like that, I imagine it happened as a result of trying to free the crank manually with a torque wrench or something. As I found out, the valves were locked so solidly with debris and rust that I had to hammer them out, so forcing an engine to turn in that condition that was bound to cause damage. But anyway, new rods are on order.

Speaking of valves, all 8 have been replaced. The main problem here was the valve seats. They are heavily pitted, particularly around number 2 and 3 exhaust ports. The seats should ideally be replaced but the plan is to get the engine running first and see what else is wrong then plan a full rebuild later on, so I’m going to defer replacing the valves seats until then. For now I just did my best to get some compression by over-grinding the exhaust port valves – far from ideal, and it was hard work on the hands, but it should at least run.

The rocker assembly is in good condition; it only needed a good degrease and a clean in isopropanol. Even the adjusters are fine and didn’t shear off or disintegrate into dust when I tried to free them.

I’ve rebuilt the carburettor using the “expensive kit” and amazingly it went back together in the right order with no parts left over. Having done that I almost understand how a carb works now, but only just. The manifold has also been given a thorough clean and de-rusting, inside and out. No point filtering the air if you’re just going to add particles of rust to it at the last moment. Much supermarket cola was used in the process of de-rusting and it got messy. I might put out a video about that one day, but only if I don’t look like a total idiot. Partial idiot I can live with, but not total.

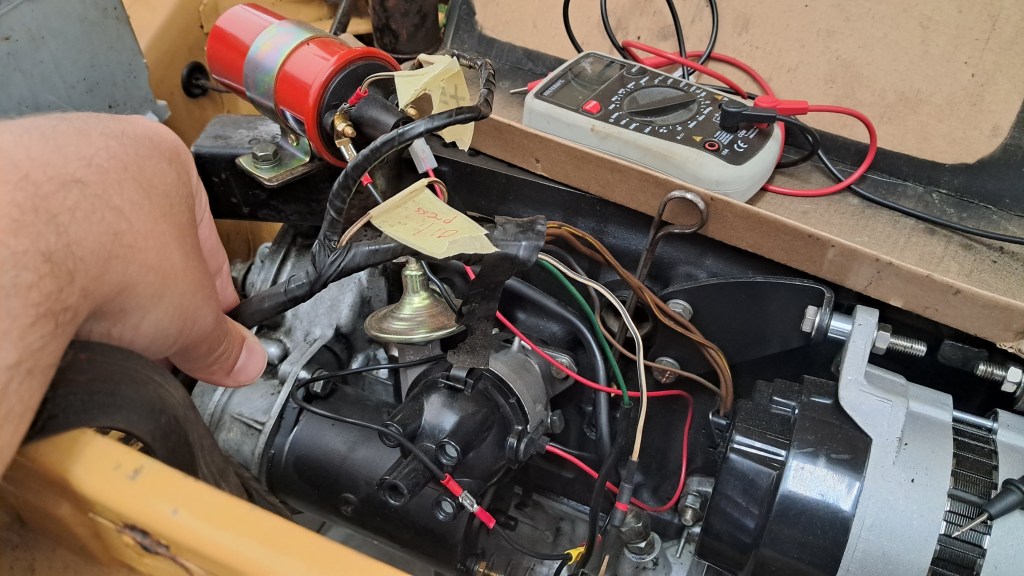

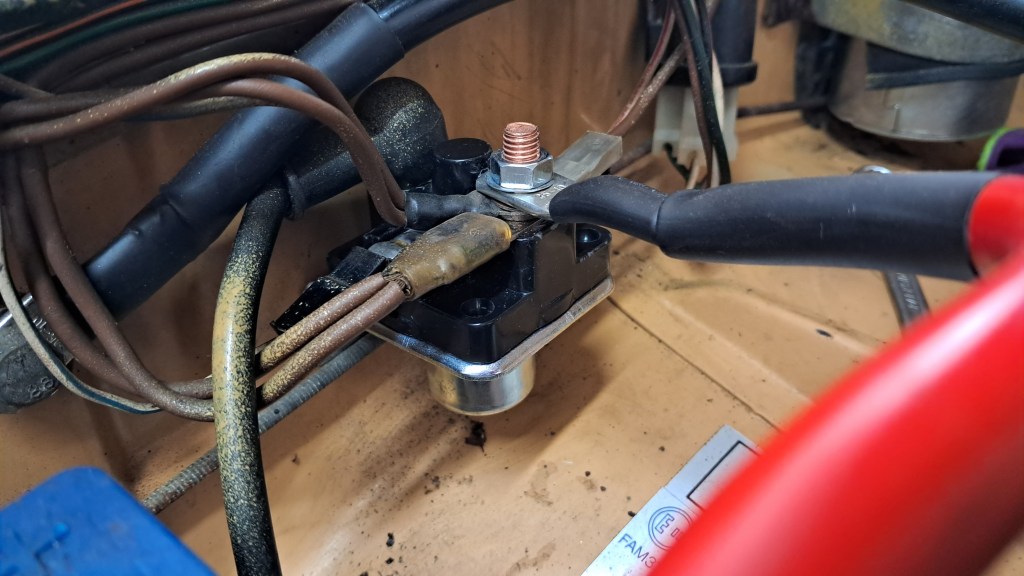

Finally I’ve begun putting the ignition electrics back together. A little guesswork needed as the wiring is, as usual, not exactly what’s documented in the Haynes manual – but never mind! Some block connectors have also been replaced, and a new starter solenoid has been installed; it now makes a very satisfying “CLACK!” when the ignition key is turned.

What’s next? Just waiting for a stud kit to arrive from Mini Spares and now another order with the new pushrods. Then we can pop the head back on, connect the fuel and see if she fires up.