Towards the end of last year I noticed the problem of coolant leaking from around the engine head studs was getting worse. My solution of “ignoring it” wasn’t having much of an effect, surprisingly. After running her up to temperature one day the coolant was freely bubbling out of all the studs and even from the head gasket itself. This clearly wasn’t going to fix itself. It was time to take the head off!

This was pretty straightforward as I’d only replaced the head in May 2023 after installing new valves, so it came apart very easily and the cause of the problem was pretty clear: I’d made a beginner’s mistake and forgotten to tighten up the head studs! Most of them were barely finger tight. Obviously the cylinder head didn’t have a reliable seal with the head gasket but – as it turns out – the holes that the studs screw into lead directly into the water jacket and have to be tight to stop the coolant escaping.

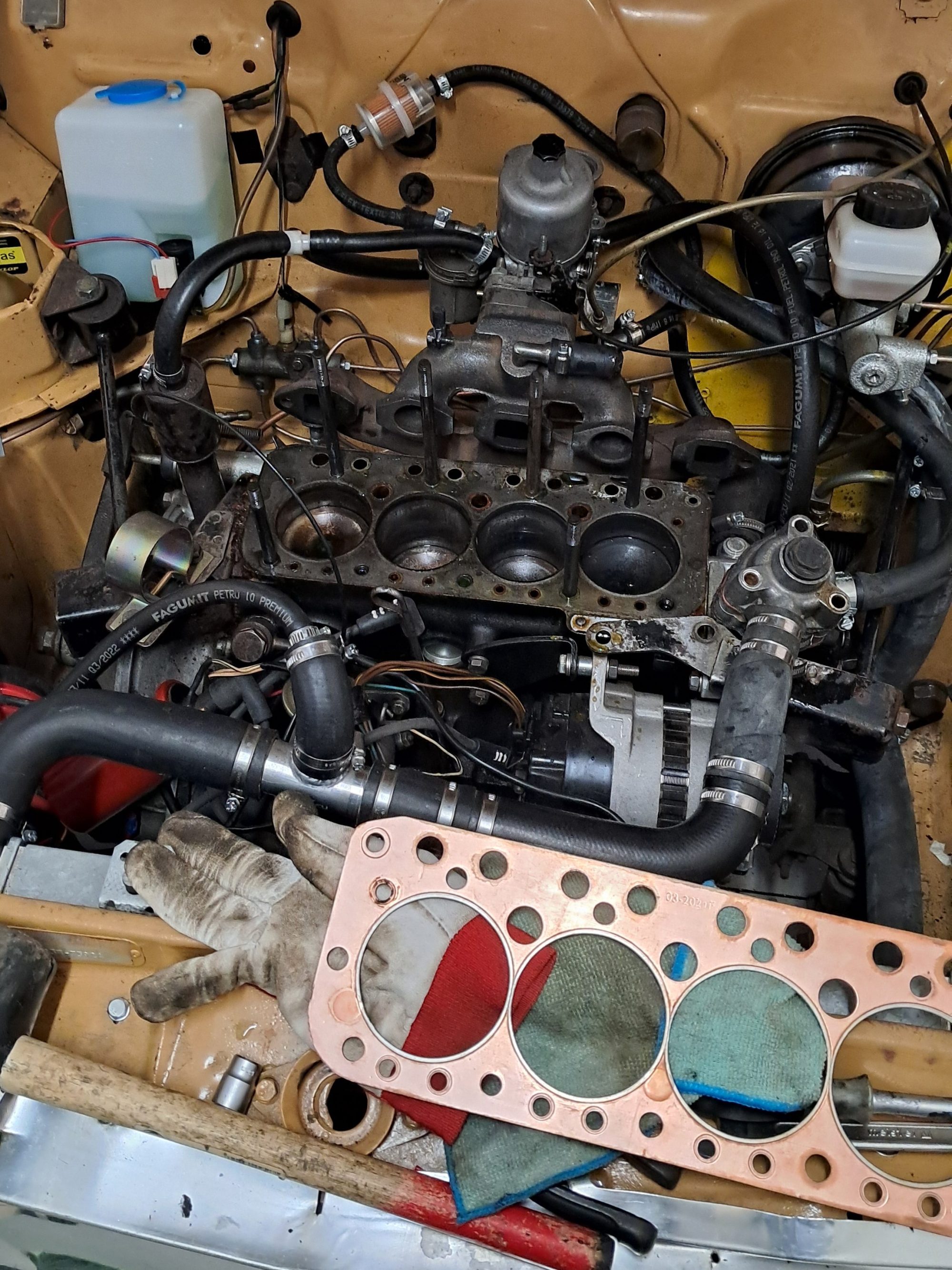

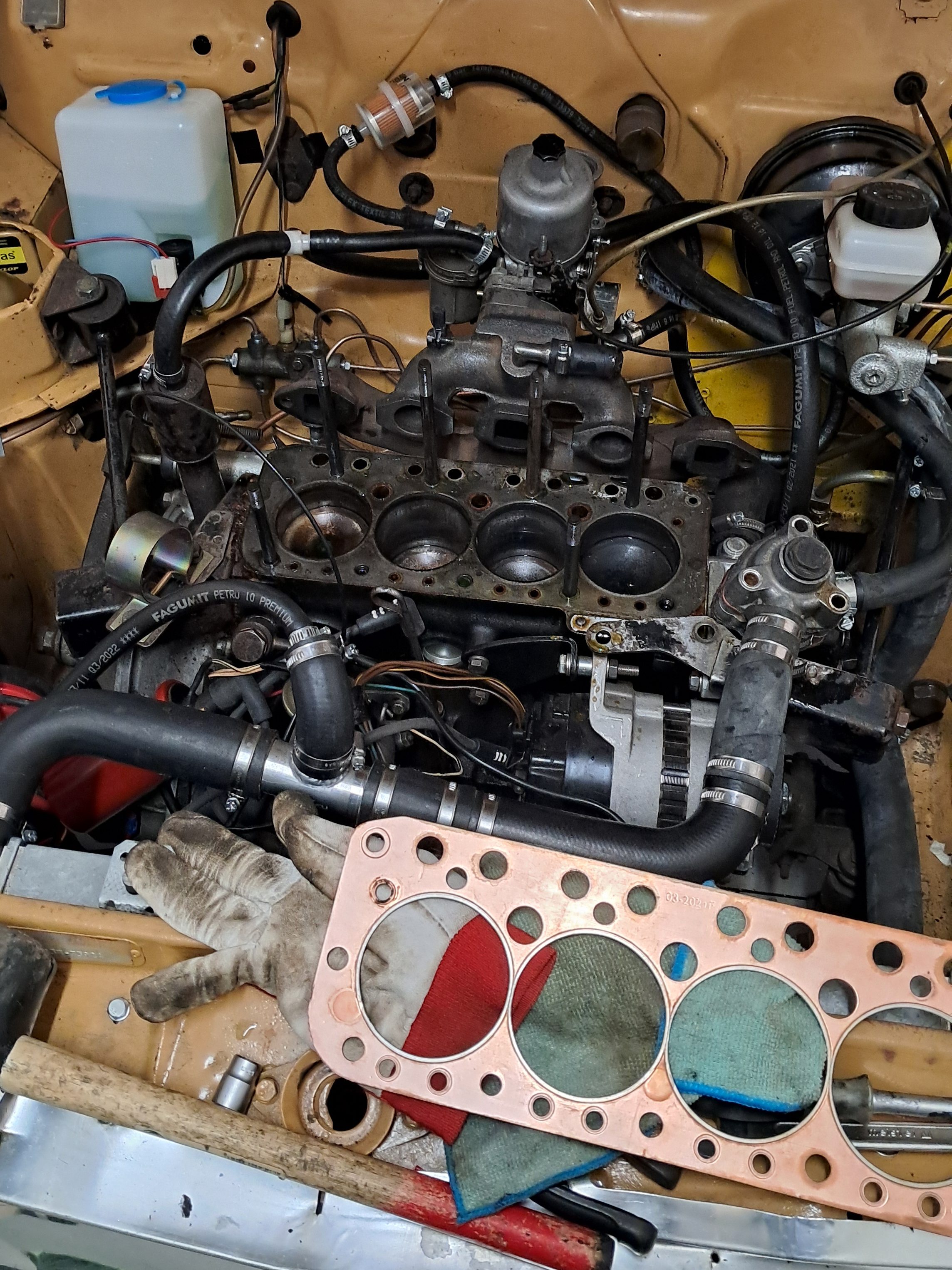

The cylinder head surface itself didn’t have any obvious defects, warpage or signs of head gasket failure so I didn’t bother getting it machined. The pistons and valves, however, were caked-up with black, oily deposits. It wouldn’t surprise me at all that the piston rings need replacing but I’ll save this for when it gets a complete rebuild, after Agnetha has been tested and registered.

Having thoroughly cleaned all the studs and surfaces I made sure the studs were tightly screwed into the block this time using the two-bolt method and a healthy glob of Loctite on each thread. With a new gasket and the nuts tightened, she started up first time with no issues and got to temperature without a drop of coolant spilled. After cooling down, I retorqued the nuts and still no puddle of coolant on the floor. Just the usual puddles of steering rack oil and brake fluid, but we’ll cross those legs when we get to them.