Executive summary

Q3 represented a period of steady activity. Agnetha participated in multiple engagements, including the weekly Wrocław z Gratem meetup and a visit to the Wena Motor Museum, achieving her furthest recorded distance from base to date, not to mention a couple of shopping trips to Lidl and Biedronka. Key performance indicators demonstrated ongoing roadworthiness, with 290 km travelled and no breakdowns.

Engineering outcomes were, umm, mixed. Boroscope inspections confirmed the urgent need for a full engine rebuild due to cylinder wall damage and oil loss. This aligns with earlier assessments that outstanding technical debt, likely accumulating since the early 1980s, would need to be addressed sooner rather than later. It is also the most plausible single reason as to why she was taken off the road in 1989, not to return for 36 years.

Looking ahead, Q4 activities will be dominated by the engine rebuild, alongside preventative maintenance on the chassis and suspension. These interventions are expected to position Agnetha for a return to service in Spring 2026.

1. key performance indicators

| Odometer(a) | 12345 km |

| Distance travelled this quarter(b) | 290 km |

| Furthest distance from home | 30 km |

| Breakdowns | 0 |

a)Odometer is undercounting due to faulty speedo cable, which makes it even more weird that when I checked the odometer *after* ripping out the engine it was stopped at 12345 I mean what the hell is that?

b)Estimated due to incorrect odometer readings.

2. MEETINGS, SHOWS AND OUTINGS

Wrocław z Gratem Meetup, Magnolia Park, Wrocław, 22nd August 2025

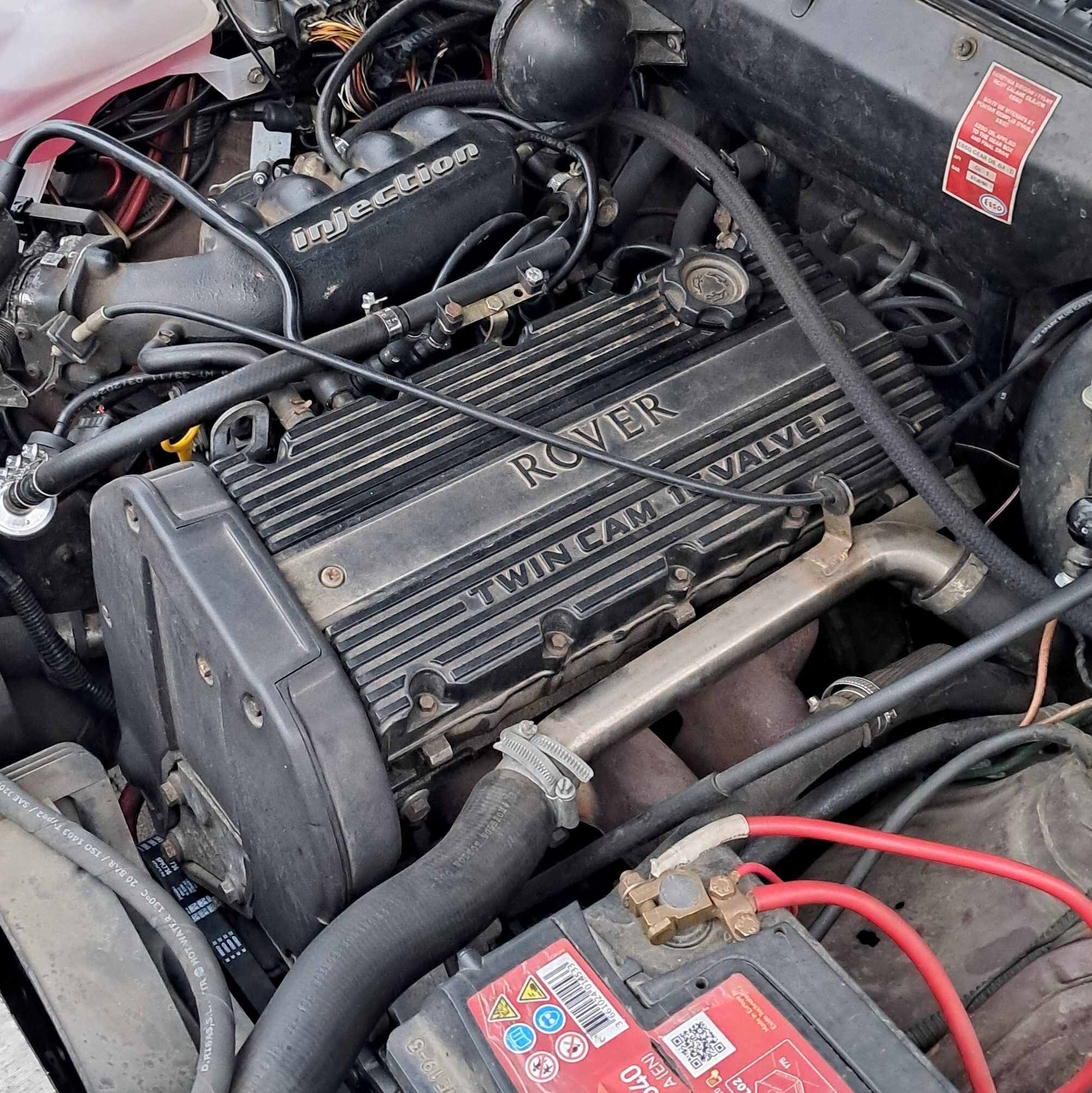

Agnetha had a surprise encounter in Magnolia Park with a fellow Longbridge stable-mate, a late model Rover 45 brought by visitors from the Netherlands.

Another surprise was the sheer number of Rover K-series engines attending the meeting, thanks to the 45 showing up and the popularity of the engine with the FSO tuning scene. For a time, FSO had a 1.4 litre version of the K-series as an engine option for the Polonez Caro and Caro Plus. Although light and powerful, it was an expensive option, so the more meat-and-potatoes GM engines were the preferred choice.

I’m told these days there are more K-series-powered Polonezes than ever before, some with a lot more capacity than 1.4 litres, and no shortage of engineless Rover 25s, 45s and 75s piling up in scrapyards all around the country!

Muzeum Motoryzacji Wena w Oławie, 23rd August 2025

One of Planet Earth’s more startling examples of a hobby that got out of hand, the Wena Motor Museum is a must-see for any car enthusiast. And if you bring a classic car you’ll be invited to park in the middle by the friendly car park attendant.

This was Agnetha’s furthest travelled distance from home to date and unexpectedly her last trip of the season. On the way out the exhaust clamp came loose and, due to a persistent tailwind, it got a bit hairy with the fumes, even with both windows down. Heading into the wind on the return trip it was more survivable although at 90 kph I was once again attacked by petrified Swedish foliage blasting out from the vents. After this trip I noticed oil spatters around the end of the exhaust, and on checking the oil level she had lost about a cupful over just a short trip. Not a great sign.

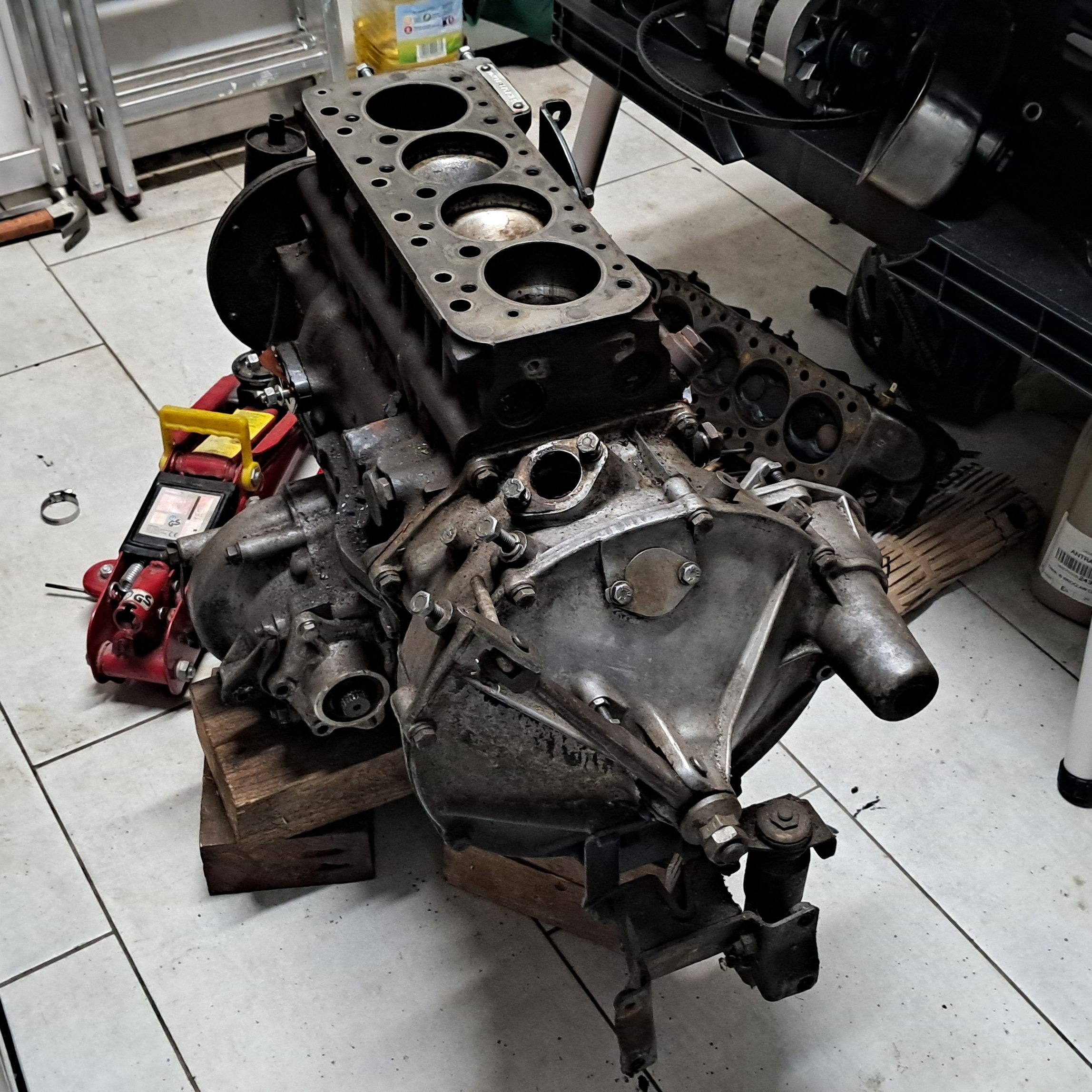

Using a cheap boroscope I had a peak through the spark plug sockets into the cylinders. Each piston had a pool of oil and the damage to the cylinder walls was very obvious – game over!

Since her first start in May 2024 I knew she badly needed a full rebuild but at that time I had the rest of the car to fix as well, so my hope was to get her back on the road for at least one summer and have some fun. This much she gave, so I’ll call it a success, and now the debt must be paid.

3. ENGINEERING WORK

The focus of engineering activities this quarter were:

- Removal and teardown of the engine

- Diagnosis of the oil fouling situation

- Assessment of necessary repairs and options for spare parts

3.1. COMPLETED

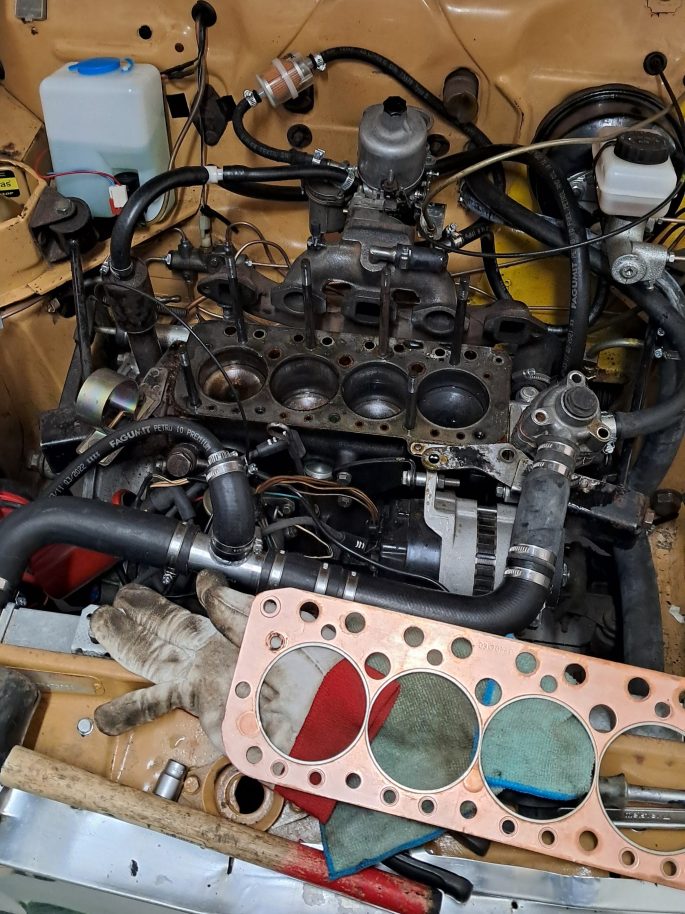

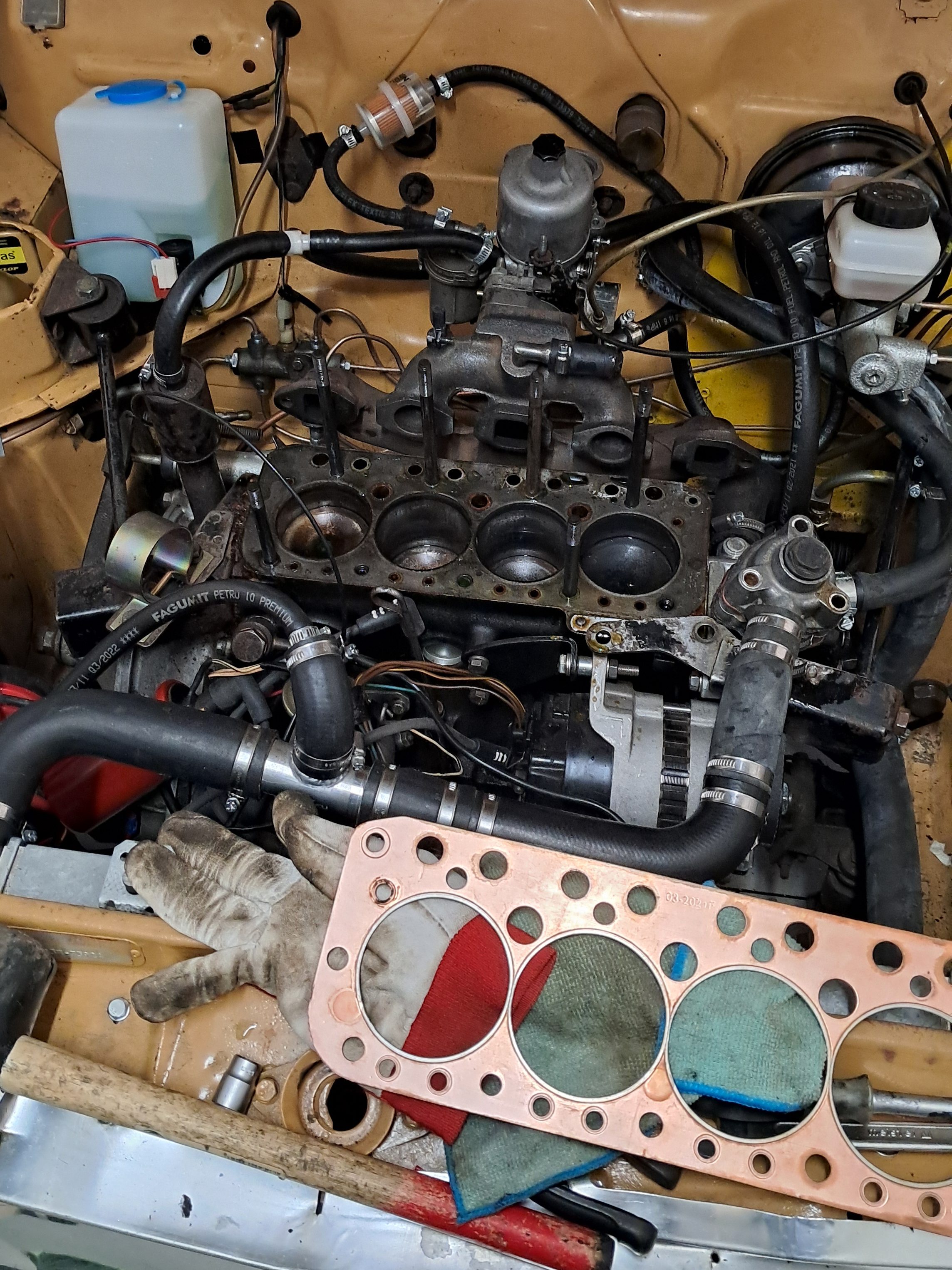

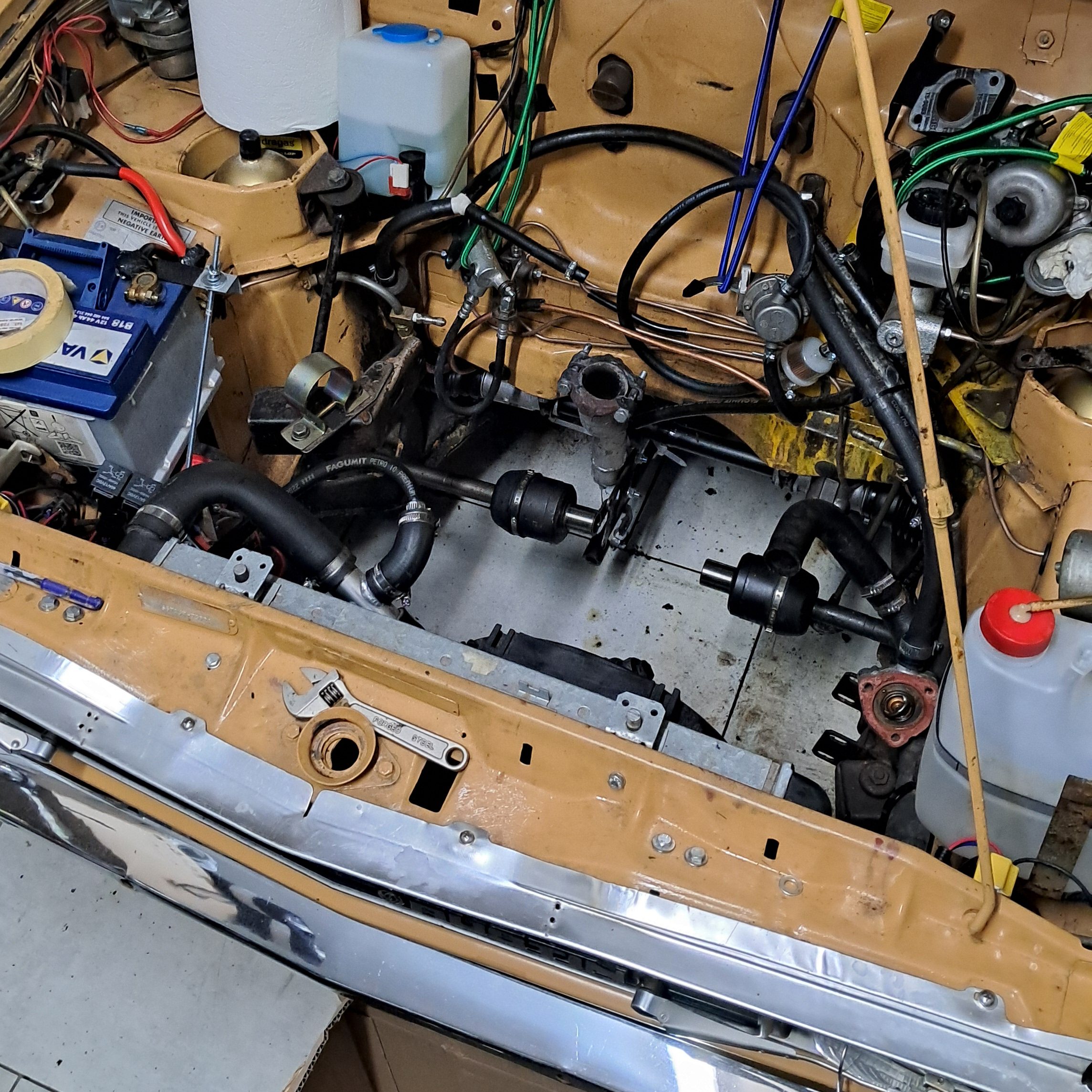

Engine Removal and Teardown

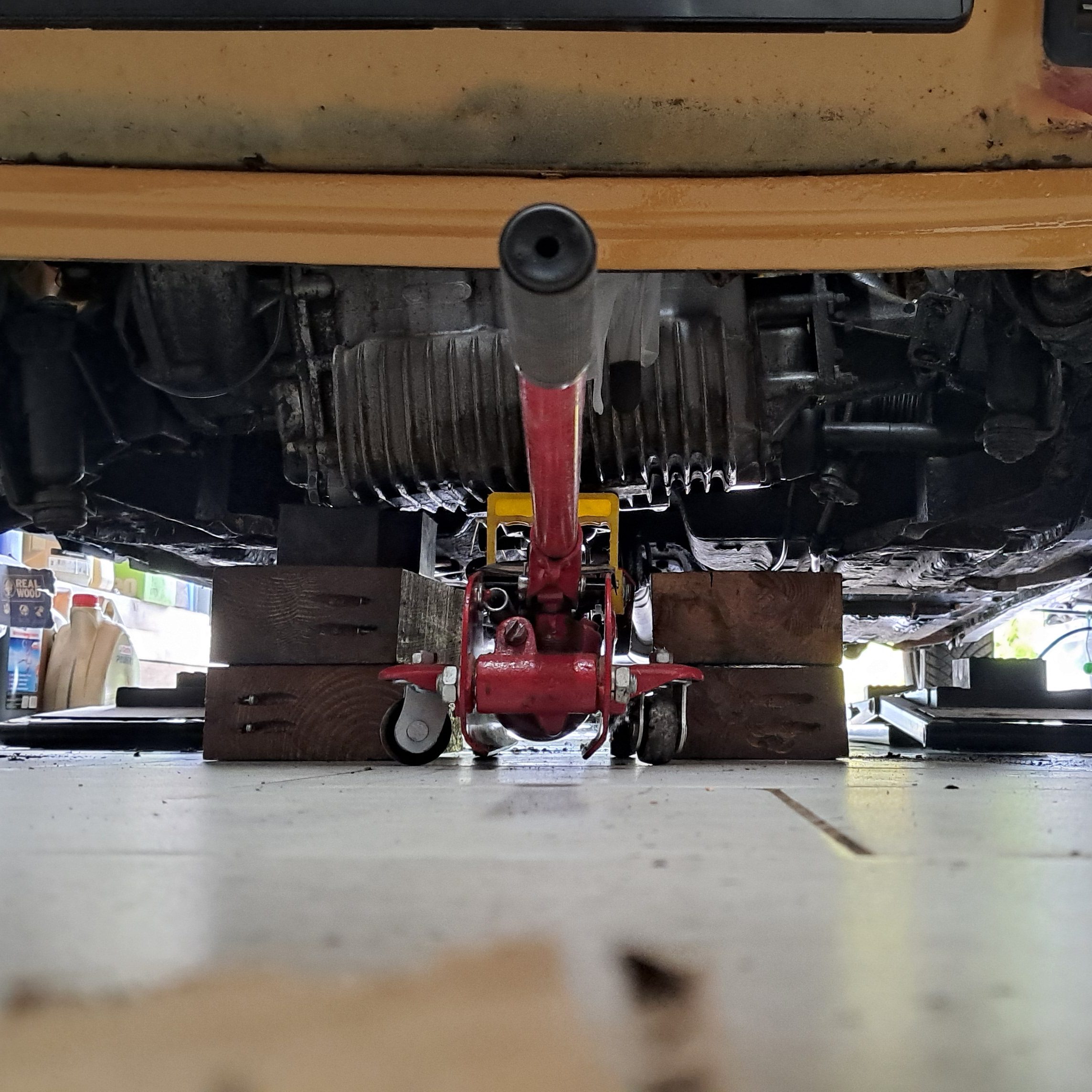

The engine was removed without a crane by lifting the body off the engine with the QuickJack, supporting the engine from underneath with wooden blocks and a floor jack. There was just enough clearance to pull the engine from under the car as long as the head was removed in situ beforehand, so it’s important to remember the head should also be fitted in situ after refitting the block in the engine bay – otherwise sad trombones all round when it won’t fit back under the car.

Contrary to the Haynes Book of Lies it was not necessary to disassemble the swivel hub assembly to remove the driveshafts from the diff. I wanted to avoid doing this because it also involves removing the callipers, draining the brake fluid, and so on. It turns out that disconnecting the swivel hub at the upper ball joint and at the trackrod end provides enough wiggle room to pull the driveshaft out of the diff. Besides which the brakes work fine – I’m supposed to be doing the engine not the effing brakes.

Oil Fouling Diagnosis

The root cause of the oil fouling was worn crankshaft thrust washers and worn main bearing shells allowing excessive lateral movement of the crankshaft. In short: Worn-out bottom end! This allowed the pistons to squirrel around inside the cylinders, scraping the cylinder walls with each stroke (as proven by horrendous witness marks on the pistons) resulting in excessive and uneven wear to the cylinder walls which, in turn, led to oil leaking around the piston rings and into the combustion zone. The widespread corrosion damage resulting from several decades of disuse was also not helping.

This degree of wear requires a lot of time and effort to accumulate. With over 123,000 km on the clock and a history of poor maintenance and neglect, we can assume that this is perhaps the main reason Agnetha was taken off the road 1989. There might have been other issues, but with oil fouling she would surely have failed her emissions test, an expensive engine rebuild was “off the table”, and so she was taken off the road and parked up…until 2025!

Repair Assessment

The block was sent to HT for assessment. Their recommendation was to bore the block out by two standard sizes to 1311cc. Oversized pistons have been purchased from MED Race Technologies along with a choice selection of fast road upgrades like-for-like(c) replacement parts.

The crankshaft is well within tolerance and shows no sign of uneven wear; it just needs a wee buff. The gearbox is in good condition, exhibiting no noticeable play or excessive wear on the gears. Apart from a good clean-out, no further work is needed.

Meanwhile at the cylinder head, the inlet valves seats need to be recut and the exhaust seats should be replaced completely with hardened seats better suited to unleaded petrol. All-new valves will be required by default, and the rocker assembly is certainly passed its best (if those rattling Pressed Steel assemblies ever had a ‘best’).

c) as in “this original part is like something retrieved from a sunken tractor, and it makes clear economic sense to swap it for this lightweight aerospace alloy component, which is more like what British Leyland should have put in there in the first place.”

3.2. PLANNED FOR Q4

The planned items are all focused on having the bottom-end “ready to go” by the end of the year:

- Cylinders bored-out and honed, deck and crankshaft polished (outsourced to HT).

- Speedo cable and gearbox attachment fixed.

- Exhaust-to-differential mounting points repaired/rethreaded.

- Bottom-end reassembled and reattached to transmission.

- Timing mechanism reassembled and clutch/flywheel assembly installed.

- Out of scope: Anything related to the cylinder head (planned for Q1).

While the iron donkey is out there are some 10-minute jobs(d) to do in-between the engine work:

- A crack has formed on the passenger-side chassis leg and needs welding shut.

- Both of the filler necks connecting to the fluid chambers of the front Hydragas displacers are too far forward, causing them to knock against the chassis legs. A bit of brute-force realignment should fix that.

- The front suspension bump-stops disintegrated long ago. Replacements are in stock but installation requires depressurising the suspension and removing the displacers; this will happen anyway to repair the chassis legs and fix the knocking problem, so it’s a good opportunity to change the bump-stops as well.

- A little preventative maintenance to remove surface corrosion, repaint and seal some surfaces that are looking a bit sad.

d)Minutes or hours? Are they interchangeable?

4. OUTLOOK FOR NEXT QUARTER

The Q4 priority is the full renovation and reassembly of the engine block.

Agnetha will be off the road for the rest of the quarter and likely for a good portion of 2026 Q1, but it’ll be winter, everyone will be spreading COVID around and the weather will be shit anyway. She’s on track to return to the road in time for Spring with a rebuilt, reliable, smooth-running and 100% stock engine.